Magnet Technologies Center (MTC)

Recent advances in superconductor (SC) technology, especially high-temperature superconductors (HTS), have revolutionized industries from defense and transportation to energy, medicine, and basic science. GA's SC magnet development takes place at its Magnet Technologies Center (MTC) in San Diego, California. The MTC is a state-of-the-art facility that builds on GA's 50-year history of developing large and innovative magnets for energy, defense, medical, and other applications.

Magnets employing SC material can achieve significantly higher magnetic fields at much greater efficiencies than those using non-SC materials. SC magnets are unique enablers for industrial and science applications such as nuclear fusion, medical diagnostics, and particle accelerators. HTS magnets in particular offer considerable promise for such applications due to their higher fields, reduced complexity, and smaller footprints.

Among other work, the MTC is the home for GA's ITER Central Solenoid project, an initiative that required significant first-of-its-kind magnet development. Our team of highly skilled engineers and technicians can perform all stages of design, engineering, and fabrication for the largest and most powerful SC electromagnets. We have significant experience with custom projects intended for the most demanding applications in science and medicine.

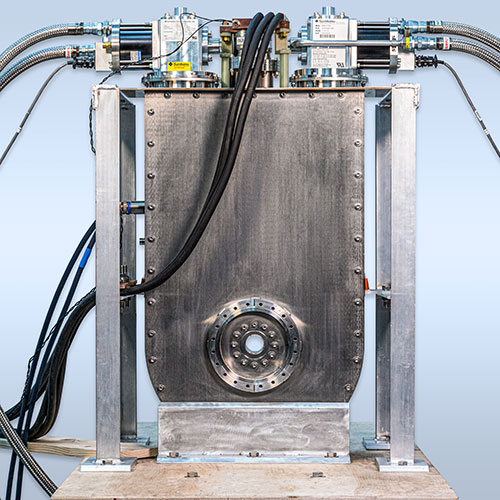

Over the past several years, the MTC has successfully expanded its core capabilities in developing HTS magnet technology. The HTS magnet laboratory at MTC recently developed a 40-mm warm-bore, non-insulated magnet wound from 500 meters of 12-mm REBCO tape. This innovative double-pancake design uses conductive cooling, rather than immersive methods (i.e., no active cryogens are inside the magnet housing) and is capable of producing fields in excess of 6 Tesla at the axis when operated between 4 and 15 K. It has been successfully tested at currents up to 700 amps in steady-state operation.

History

GA has a 50-year history in magnet technology development as part of its DIII-D fusion research program for the U.S. Department of Energy. GA has been working on SC magnet applications since the mid 1980s, and through these efforts, GA has developed multiple large SC magnet systems. These include more than 1,000 magnets for MRI applications, homopolar motors, as well as several defense applications.

GA magnet technology has supported key defense programs such as the Electromagnetic Aircraft Launch System (EMALS) being deployed on the next generation of U.S. Navy aircraft carriers, and the Holloman High Speed Maglev Test Track project built for the U.S. Air Force at Holloman AF Base in New Mexico. This latter system holds the world record for fastest speeds achieved on a maglev system.