SiGA SiC Composite

Silicon carbide (SiC) has been used for a wide variety of industrial purposes for more than 100 years. Its high hardness and ability to survive extremely high temperatures make it ideal for demanding applications such as cutting tools, refractory components, and high-power electrical systems. It has also been used for certain nuclear energy applications such as coating TRISO fuel particles, but its brittleness in pure form limits its use as a structural material. However, it can be significantly toughened to address this brittleness by reinforcing monolithic SiC with SiC fibers (forming a composite known as a ceramic matrix composite, or CMC). This approach has been explored since the 1990s, but difficulties in manufacturing, as well as problems with joining composite components, made deployment impractical.

General Atomics Electromagnetic Systems (GA-EMS) has decades of experience working with silicon carbide and began its current work on SiC composites for nuclear fuel cladding applications in 2009. Leveraging past research with new technologies, GA-EMS scientists have developed SiGA®, a high-tech engineered SiC composite material that forms the basis of its Accident-Tolerant Fuel program, which is developing nuclear reactor fuel rods that can survive temperatures far beyond that of current materials. GA-EMS is also using this advanced material technology to offer SiGA® components for applications beyond ATF.

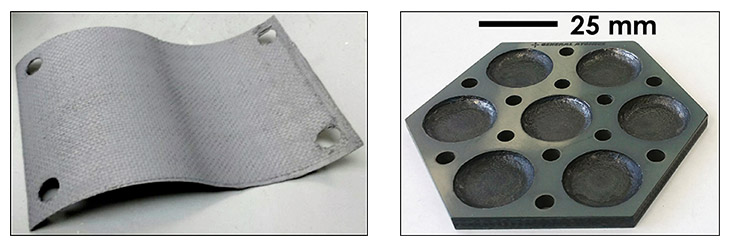

GA-EMS can fabricate SiGA® composite in complex planar, tubular, and custom geometries. Our proprietary joining method can bond SiC to SiC, and SiC to other materials, in a variety of configurations. Such joints retain their integrity and hermeticity at high temperatures, pressures, and neutron fluences. Finished SiGA® composites maintain their strength and stability under high levels of irradiation and can retain strength at temperatures well above 1600°C.

SiGA® composite components are available in tube diameters from 5 mm to >50 mm, and tube lengths up to 1 m. Hot-Pressed structures with thickness >25 mm can be produced, and both blind and thru-hole features can be manufactured near net-shape without machining.